Hardware Configuration Items in As-X Configuration Management by Aerospace & Defense Contractors

Part 2 of 2

Your new aircraft control system has gone through all the reviews and audits (e.g. SRR, PDR, CDR, FCA and PCA as referenced in Part 1 of this CMsights article) and you are ready to deliver your first unit/lot number to your customer. You have diligently assigned Hard Ware Configuration Items (HWCIs) to the control system top assembly and its sub-systems based on their criticality to system functionality. You have also defined lower-level HWCIs that are designated as spares for the planned 50 fielded systems. One of these is a Printed Wiring Assembly (PWA). Your digital thread is complete from the requirements documents through to the As-Designed configuration for your HWCIs.

You have prepared the acceptance documents and are about ready to give them to the customer to sign. She holds her pen back as you move the papers across the desk, looks you in the eye and asks you for the section in your Configuration Management Plan that covers management of the rest of the As-X configurations.

You think to yourself, “Wait … isn’t the only As-X configuration always the As-Designed configuration?” The engineering voice in the back of your mind whispers, “No way, the As-Designed configuration is just the starting place.”

The Challenges of As-X Configuration Management

The As-X’s are the configuration of a HWCI throughout its lifecycle. For aerospace and defense contractors HWCIs are identified for products, critical components, spares for fielded equipment, or complete weapon systems during stages that can last over many years of production and service life, including:

As-Designed – the released Bill of Materials (BOM)

As-Built – what is in the fabricated item including

variances

part substitutions

As-Tested – what was tested plus

accounting for simulated items

As-Shipped

includes identification of any ship-short items that will be delivered and installed later

As-Delivered – the final configuration including any ship short items

As-Fielded – includes items added by the customer

As-Maintained – includes all

routine maintenance

subsystem or component replacements

upgrades

As-Disposed – final disposition of the item and its components

Questions often arise during a program that have a distinctly HWCI flavor to them such as:

What was the state of the engineering design at PDR for this HWCI?

g. what is the released revision of the associated documentation?

What was the state of the engineering design at CDR for this HWCI?

What was the state of the engineering design at the Test Readiness Review (TRR) for this HWCI?

What changed between CDR and the start of FCA and PCA for this HWCI?

What are the As-X configuration for each HWCI deliverable?

If more than one copy is being delivered this must be answered for each copy

The challenge for configuration management solutions is that these software tools need the capability to provide and manage the released revision of the associated documentation at any point in time so the above comparable questions can be answered, and done so by users who may not be CM experts. Engineering-centric PDM or enterprise-level PLM solutions, with bolt-on CM functionality developed primarily to support the needs of the design engineer whose responsibilities are focused on the As-Designed configuration, may not be able to deliver this functionality and usability.

As-Built configuration for multiple units being made to the same As-Designed configuration may be very different when they are delivered due to two reasons: part substitution and variances.

As-Built Configuration Differences Due to Part Substitutions

Meeting specification requirements for performance life and reliability is calculated based on the As-Designed configuration. However, serial number/lot numbers built with a single part substitution may result in slight differences in performance life and reliability for that serial number or lot number. Field anomalies can’t be investigated based on the As-designed information alone. To truly understand what is going on with the unit in question you need to know what is inside the unit itself throughout its life-cycle. This is where capturing the As-X data is crucial in the configuration management software.

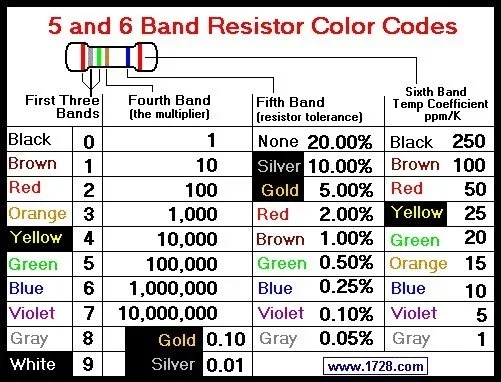

The concept is easier to understand if we examine the case of a single resistor on the HWCI for the PWA in an aircraft control system. PWA’s can contain over 50 resistors. Any of these called out in the As-Designed BOM will have authorized part substitutions. Resistors with better tolerance, temperature coefficient and cleanliness can be substituted for the one specified in the engineering BOM. Let’s explore each case in turn to find out how many equally viable substitutions there are for a single resistor. We will assume the PWA BOM calls out a 1/4th watt 100-ohm resistor with:

Fifth band resistor value tolerance + or – 5.00% – Gold band

Sixth band temperature coefficient of 250 – Black band

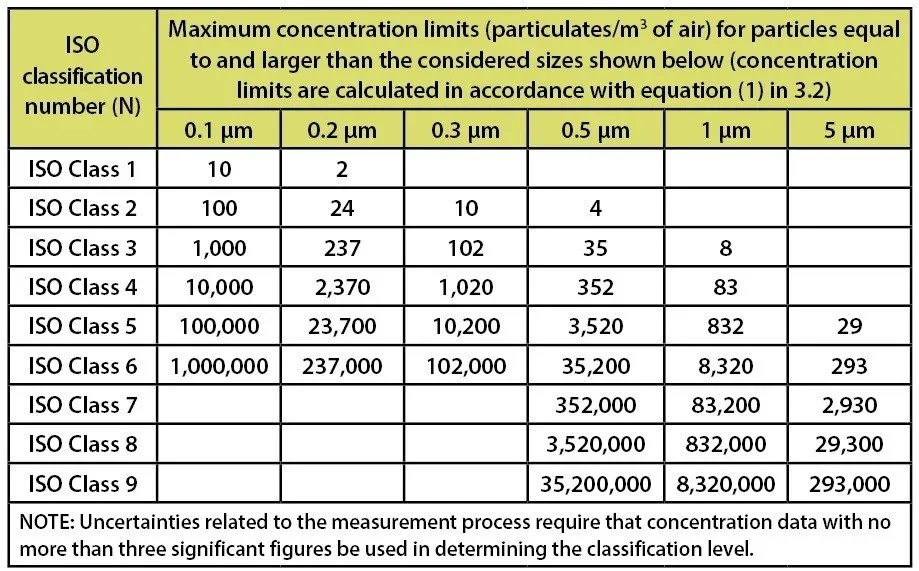

Cleaned for use in an ISO class-4 clean room

Image from http://www.1728.org/resisclr.htm Copyright © 1999 - 2018 1728 Software Systems

Substitutions for resistor value tolerance: A 100-ohm resistor with a gold band tolerance + or – 5.00% (i.e. the 100-ohm gold band resistors will measure between 95 ohms and 105 ohms). There are six resistor value tolerances that are better than a gold band. They are identified as the Red, Brown, Green, Blue, Violet, and Gray in the table.

Substitutions for resistor temperature coefficient: The sixth band temperature coefficient or “tempco” represents the amount the color-coded resistance value will change with temperature. A lower tempco number means that when hot the 100-ohm resistor value drifts less. A sixth band tempco of 250 can be replaced by any resistor with a lower tempco number. There are eight of them identified as the Brown, Red, Yellow, Green, Orange, Blue, Violet, and Gray in the table.

Substitutions for resistor cleanliness: A resistor cleaned for use in an ISO class-4 clean room can be substituted with the same value resistor cleaned to a more stringent cleanliness level. There are three of them ISO class-3, class-2, and class-1 levels.

Selected airborne particulate cleanliness classes for cleanrooms and clean zones. Classification Parameters from ISO 14644-1

When we do the math, we find there are six possible tolerance substitutions, eight possible tempco substitutions, and three possible ISO cleanliness substitutions. This results in 144 (6 x 8 x 3 = 144) viable part substitutions for that one BOM-specified resistor!

This means that if you produce 145 units you may have that many As-Built configurations that need to be tracked in the CM software (144 substitutions + 1 with no substitutions).

To make it even more complicated, we can also have As-Built differences due to approved variances. Variances come in two types:

Minor variances where the part can be repaired or used as-is (single unit or lot) such as:

a metal part has a scratch on it that does not affect its intended use

a unit or lot has a minor blemish in the coating that does not affect its intended use

Major variances where the HWCI or a subsystem of the HWCI does not meet specification requirements:

major variances before something is built such as an analysis of the requirements after allocation shows the best reliability that can be achieved is 0.99998 rather than the specified reliability of 0.99999

major variances after something is built such as the item is required to operate at -40 degrees centigrade but is found during test to only operate at -39 degrees centigrade

in either case the major variance is for a limited number of units which is known as a limited effectivity

Let’s assume that out of our 145 As-Built PWAs 50 are installed in the delivered aircraft control systems. The remaining 95 are sold as spares to be used during the maintained phase of the control systems life. Each time one of the spares is used to replace a damaged PWA the As-maintained configuration for that control system is changed.

If you expand this to include all 50 resistors on a typical wiring board then there are 145 PWAs x 50 delivered units = 7,250 possible As-Maintained PWA configurations due to a single resistor!

Similar considerations exist in all components and mechanisms contained in a delivered product. This includes part substitutions for capacitors, connectors, inductors, LEDs, switches and other wiring assembly components as well as the printed wiring board substrate material.

Importance of the As-X Digital Thread

So why is this digital thread throughout all phases of a hardware configuration item’s life so important? Due to the critical nature of the aircraft control system in our example the entire fleet of 50 aircraft is grounded if one of the installed PWAs fails. It will stay grounded until you complete a root cause analysis to determine if the failure impacts all, a sub-set of, or a single delivered unit(s). Without the entire digital string through all the As-X configurations the root cause analysis for the failed PWA SN the task will take months instead of hours to analyze simply because you have no idea what parts were used in that specific PWA or the HWCI it goes into.

The practice of effective configuration management for aerospace and defense industry contractors does not end when the engineering changes are all released defining the As-Designed configuration. The current configurations for each SN also needs to be tracked for each unit throughout its life-cycle. This is done via the digital threads in configuration management software like those inherent in CMstat’s PDMPlus. We’ll continue to examine the application of CM in digital threads as well as in IoT in future CMsights posts which you can follow here. Until then, request a live demo of how PDMPlus is used by A&D contractors to manage all of the As-X configurations over a long product lifecycle with an email to information@cmstat.com.

Receive CMsights

Subscribe to CMsights News for the latest updates from CMstat on Configuration Management, Data Management, EPOCH CM, and EPOCH DM.

Request a Demo

See how EPOCH CM and EPOCH DM support industry standards and best practices in Configuration Management and Data Management.