Configuration Management for Manufacturing and Supply Chain

Many engineering PDM or enterprise PLM software that product manufacturers have do offer some, albeit limited, configuration management functionality.

However, most users and maintainers of configuration product data are not engineers, much less configuration management experts. They do not have nor do they want access to hard-to-learn PDM software or complex and expensive PLM solutions.

Professionals working in program management, procurement, logistics, manufacturing, test, quality, and customer support simply don’t need all the capabilities and complexities of overweight PLM solutions to perform their job.

Instead, they value access to instantly-usable configuration data management tools that do not require expert skills or extensive training.

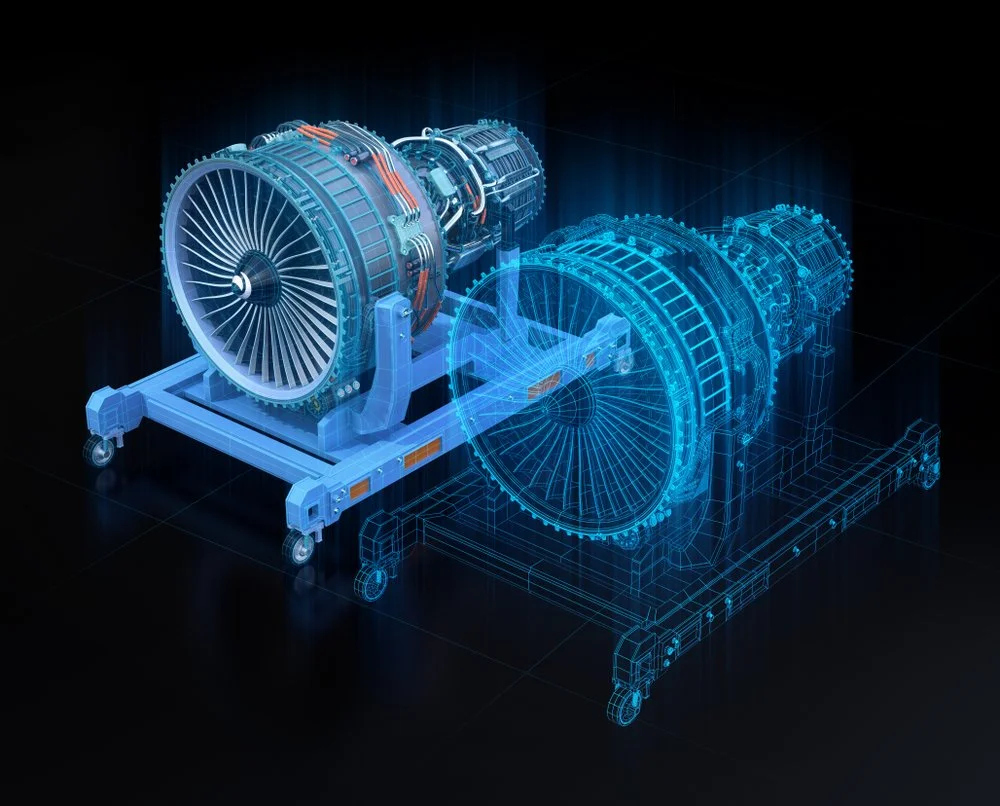

This is especially true for the supply and service chain partners of manufacturers that will be responsible for updating the As-Maintained data records and digital twin models where the in-service BOM may look nothing like the engineering released BOM.

Learn more about the difference between PDM, PLM and CM HERE, then examine what the supply chain values from the use of CM HERE.

Read about the use of Configuration Management in other industries HERE.

Receive CMsights

Subscribe to CMsights News for the latest updates from CMstat on Configuration Management, Data Management, EPOCH CM, and EPOCH DM.

Request a Demo

See how EPOCH CM and EPOCH DM support industry standards and best practices in Configuration Management and Data Management