Asset Lifecycle Configuration Management Software

Inside Asset Lifecycle Configuration Management Software :

What is Asset Lifecycle Configuration Management (ALCM)?

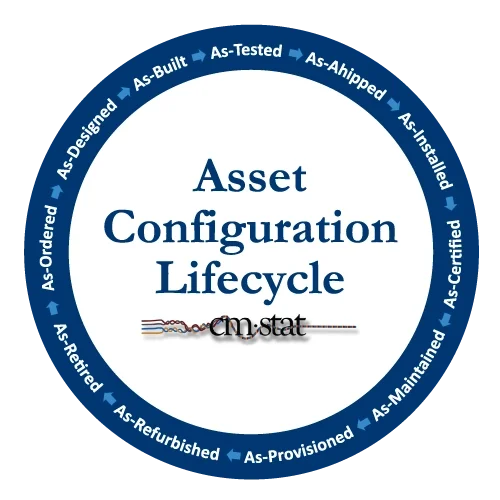

Asset Lifecyle Configuration Management is the application of configuration management principles that are focused on the management of long-life products, components, devices, equipment, systems, networks, sites, platforms, and other deployed assets over years or even decades of use.

Managing and tracking the live “As-X” configurations of as-procured, as-installed, as-deployed, as-maintained, as-repaired, and as-retired configurations of products that are far removed from the OEM’s original as-designed CAD models or PDM data vault is often the most critical use case of configuration management.

The as-maintained configuration is often very different from what was designed, manufactured, or installed. As a result, the sheer volume, complexity, and variations in the configurations of installed equipment, including part replacements and substitutions, often overwhelms legacy methodologies and tools. It becomes nearly impossible to keep all the different downstream BOMs accurate and synchronized with changes across all product variants by customer site, lot or serial numbers.

Learn more about the “As-X” challenges and problems that are addressed by Asset Lifecycle Configuration Management in this CMsights post.

How is ALCM different from Product Engineering Configuration Management?

There are many if not more uses of configuration management data and software tools outside and downstream of the traditional engineering managed configuration and change control functions within a product manufacturer. This is especially true in the supply, support, and service chains of long-life assets deployed in the field.

In these uses of CM, product engineering PDM solutions rarely provide the deep functionality, workflow adaptability, and robust usability required for performing asset lifecycle configuration management by non-CM experts in the supply and service chains.

ALCM requires expansive functionality and nimble workflow processes − without loss of usability by occasional users − for product structure maintenance, configuration identification, baseline definition, configuration items, change management, status accounting and verification.

Read more about these challenges with examples in this CMsights post on As-X Configuration Management in the Aerospace and Defense industry.

Where is Asset Lifecycle Configuration Management software used?

The use of Asset Lifecycle Configuration Management software is found in many industries which have long-life products that undergo numerous changes to their As-Installed or As-Deployed configuration over years or even decades.

These industries include: aviation, aerospace & defense, energy, heavy equipment, high-tech electronics, industrial machinery, information technology, infrastructure, medical devices, marine, mining, naval, transportation mobility, and utilities.

Professionals working in these industries who may either create, access, use, approve, or maintain configuration-related date are found in numerous organizational functions.

Their roles include: program management, engineering, manufacturing, quality assurance, tech pubs, procurement, logistics, test, compliance, sustainment, service, and MRO.

To learn more about uses of ALCM software read the CMstat whitepaper “Asset Lifecycle Configuration Management” available HERE for downloading.

What are the important functions of Asset Lifecycle Configuration Management software?

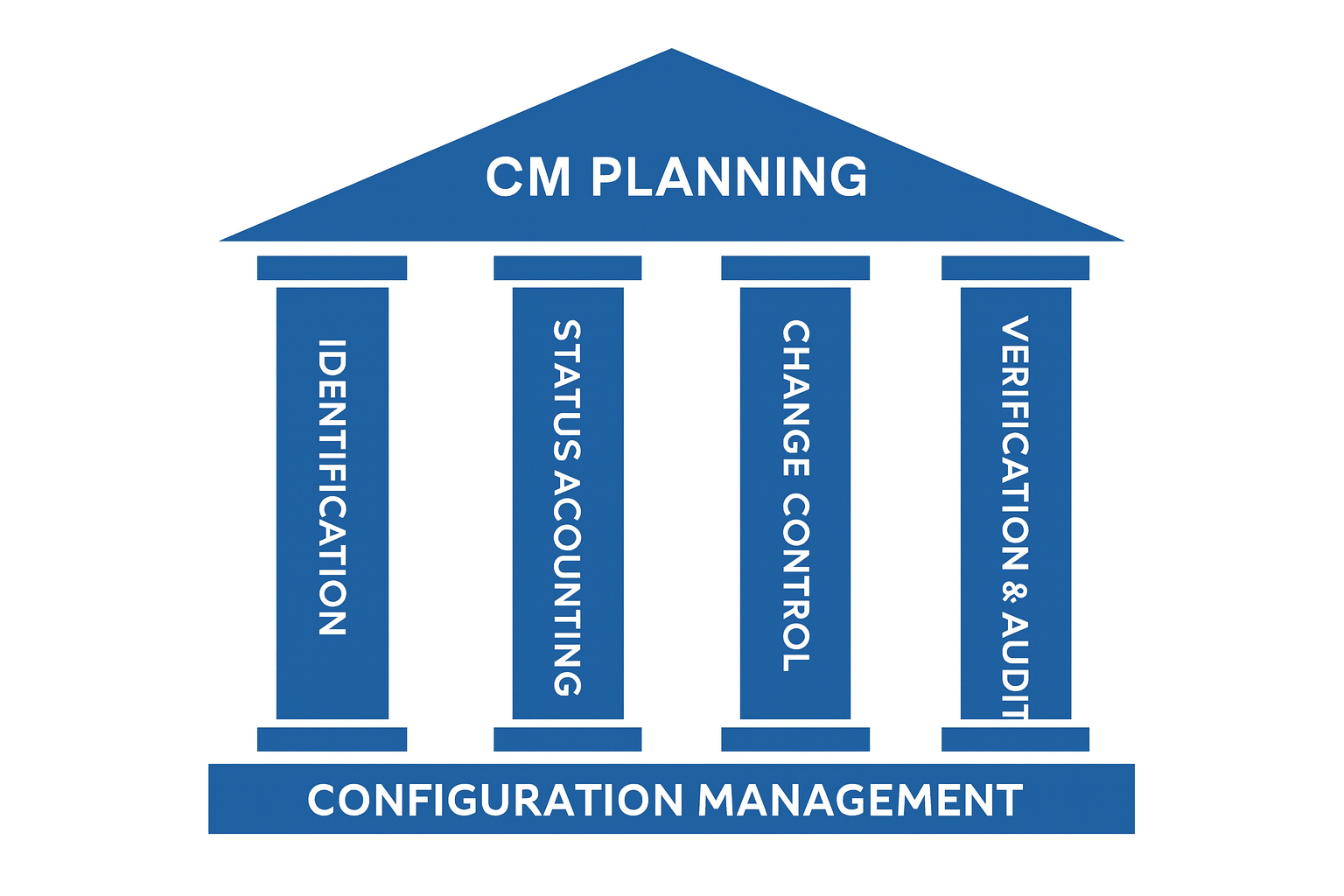

All Configuration Management software solutions must support the five foundational elements of CM. These are: configuration planning, configuration identification, configuration control, configuration status accounting, and configuration traceability and audits.

These capabilities are typically delivered by a set of core CM functions which are enabled by the following CM software features:

Product Structure Management

Baseline Identification & Specification

Configuration Item Management

Configuration Data Management

Configuration Identification & Control

Configuration Status Accounting

Configuration Rules

CM Processes & Workflows

CMII and EIA 649 Standards Implementation

Bill of Material (BOM) Management

Change Management & Reporting

Change Implementation and Impact Analysis

Change Effectivity Analysis & Management

CAD-Independent CM

Tracking of As-Designed, As-Built, As-Maintained Configurations

Warranty Management

Document Management

Configuration Planning Management

Reviews, Audits, and Compliance Reporting

LEARN MORE how CMstat’s latest product, EPOCH CM, offers the deep functionality to support all of the capabilities required of a comprehensive Asset Lifecycle Configuration Management solution.

Receive CMsights

Subscribe to CMsights News for the latest updates from CMstat on Configuration Management, Data Management, EPOCH CM, and EPOCH DM.

Request a Demo

See how EPOCH CM and EPOCH DM support industry standards and best practices in Configuration Management and Data Management