The Expanding Role of Configuration Management

Much has been recently written about the use of Configuration Management (CM) as products, equipment, systems, and infrastructures (both physical and digital) become more complex to design and maintain with frequent configuration changes over longer lifecycles of consumer use or asset deployment. As a result, the role of configuration management continues to rapidly expand and evolve, creating new challenges, opportunities and decisions for CM professionals, industry practitioners and solution providers.

With this growth in the use of configuration lifecycle data, managers are also being confronted with a maze of decisions that will have long-ranging impact on the digital transformation initiatives of their product portfolios, organizations, and supply/service chains. Summarizing a few of the technology and business trends influencing the evolution of CM — as this CMsights post and recorded panel discussion seek to do — will help managers prepare for the future while maximizing the ROI from their investment decisions.

There are a number of noteworthy trends impacting the technical scope and business value of configuration management. For many best-in-class manufacturers, CM is now viewed as an enterprise discipline that deserves as much executive support, funding, and oversight as Quality Management. Senior managers no longer think of CM as a product engineering function delegated to a few subject-matter experts working in isolated silos, much like the resident BOM spreadsheet gurus of yesteryear once did. Read more in this post on Why Configuration Management is Quality Management.

As a consequence, CM has evolved from being a version control feature of engineering-centric PDM software, then to a change management module of product-centric PLM systems, and finally to an enterprise business solution that spans across not only the OEM, but upstream suppliers and downstream service partners. This shift in the role of CM is the most significant and rewarding change we at CMstat have witnessed in over our thirty years of history. Learn more about the History of Configuration Management Software.

The industrial use of Configuration Management has its origins in the aviation, aerospace and defense industries where its application to the design, manufacture, and maintenance of aircraft, ground vehicles and naval vessels fueled the early adoption of CM. Now, the implementation of CM has become widespread across many other industries including not only Aerospace & Defense but also Energy & Renewables, Heavy Machinery & Industrial Equipment, High-Tech & Electronics, Industrial Automation and Robotics, Life Sciences & Medical Equipment, Manufacturing & Supply Chain, Marine & Naval, and Transportation & Mobility. This is another important trend expanding the career opportunities for CM professionals who can learn more HERE about the business challenges these industries have which CM can address.

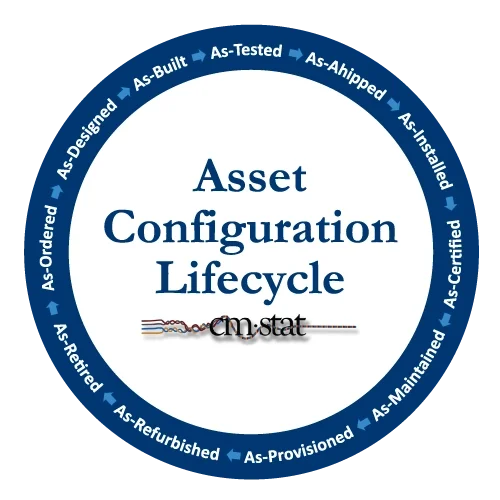

One of the fastest growing applications of CM is in Asset Lifecycle Configuration Management (ALCM). Across many industries, managing the in-service configuration of long-life assets over their extended-use lifecycle of years is a far more important use of CM than in product engineering. This is especially true in the supply, support, and service chains of high-tech equipment manufacturers whose systems are deployed, maintained, and refurbished in the field for decades. For these uses, tracking the as-procured, as-built, as-installed, as-deployed, as-maintained, as-repaired, and as-retired configuration of equipment and systems that are far removed from the OEM’s original CAD or PDM vault is the mission critical use case of CM. Learn more about ALCM here.

The move to Model-Based Design (MBD) and Model-Based Systems Engineering (MBSE) is another important trend that is expanding the use of CM while precipitating new challenges and strategy decisions. As example, managing the winding digital thread as it weaves a web flowing through digital twin models absolutely requires the sound application of CM principles, planning, and data structures as referenced in this CMsights post Digital Twins for As-Maintained Configuration Management.

A rapidly developing business trend that is impacting the future of CM is the drive to sustainability and a circular low-carbon economy. No longer can consumer products or industrial assets be mass produced, consumed, replaced, and disposed of without regard to their energy lifecycle, reuse of component parts and disposition of natural resource materials. Thankfully, asset configuration and data management methodologies and software tools, like CMstat’s EPOCH, are already available that can be deployed quickly to help collect, track, and manage product, process, and lifecycle data.

There are numerous other factors influencing the future of CM, many which we have covered in previous CMsights posts such as this article on the Future of CM Software in federated PLM platform architectures . Collectively, all these trends point to a very promising future for not just the technology of configuration management but also for the many thousands of CM professionals, solution providers, consultants, standards organizations, educators, and students around the world. During a time when there is much turmoil due to pandemics, economics, and politics it is absolutely uplifting to work in a profession that is so dynamic, promising, and motivating.

The sharing and collaboration among CM professionals is also encouraging to witness. Lisa Fenwick, CMstat’s Vice President of Product Development, recently participated in an international panel discussion on the Future of Configuration Management. The free-ranging discussion was hosted by respected PLM educator and coach Jos Voskuil who authors a weblog on PLM. The panel included Martijn Dullaart, Lead Architect for Enterprise Configuration Management from ASML and a committee chair for IpX, and Maxime Gravel, Manager of Model-Based Engineering at Moog.

Watch this video now in the recording below or on YouTube HERE and learn what these CM thought leaders have to say about the future of configuration management -– including why simple engineering change control processes within legacy PDM / PLM systems are insufficient to support the digital infrastructure needed for model-based enterprise-wide CM.

Receive CMsights

Subscribe to CMsights News for the latest updates from CMstat on Configuration Management, Data Management, EPOCH CM, and EPOCH DM.

Request a Demo

See how EPOCH CM and EPOCH DM support industry standards and best practices in Configuration Management and Data Management.