Are Spreadsheets and Shared Drives a Substitute for a CM / DM Tool Set?

This month’s post is from Dave Allen, CMstat’s Aerospace & Defense Industry Ambassador and CM training instructor for CMPIC, who recently retired as a CM/DM Director at Raytheon.

In this CMDM Coaches Corner I want to respond to a question I have heard many times over my career that impacts the performance of the Configuration Management and Data Management function within an Aerospace & Defense program:

“Can’t the combination of spreadsheets and shared drives constitute a good CM/DM tool set?”

My experience from over thirty years working in various CM/DM roles for a leading defense contractor is an emphatic “NO!” Even times when projects I supported wanted the answer to be YES.

This said, I appreciate that for those who are unfamiliar with the CM/DM function, especially senior business managers, the reason why deserves better explanation than a simple yes or no answer.

I have witnessed CM and DM professionals struggling with this same issue on a regular basis for years too many. A recent poll I undertook exposed that many A&D firms, especially in the supply chain, still rely on rudimentary (or overly complex) spreadsheets and shared drives despite their contracts often requiring better. I suspect that there are even more that still do so because what organization wants to admit that they are stuck in the 80s.

And it’s not just in A&D that spreadsheets are still being used and abused. This recent article about Formula 1 racing exposed that some teams rely on Excel workbooks to manage tens of thousands of parts across multiple cars which ended up being "impossible to navigate and impossible to update."

Many will admit privately they desperately need a different strategy that will then hasten the justification for a new set of CM/DM tools. They then go about approaching leadership only to be rebuffed with objections like:

“We will look into it in our next contract.”

“That would be nice, but we don’t have the funding.”

“It seems we are getting by just fine with our spreadsheet and internal drives.”

“No one in our program office is complaining, so what’s the problem?”

“Corporate has issued an edict for an enterprise PLM solution that I thought already does all that we need in CM and DM.”

“I don’t see any financial benefits or technical risk for changing how we do things now.”

These responses are from smart, well-meaning leaders just trying to run their business unit. While it may seem personal to the CM/DM employees who feel like they are being stonewalled, most times it isn’t that at all. More likely it’s the lack of a better (or any) business case with an accompanying Return on Investment (ROI) analysis.

Yet other times, especially in A&D programs where quality and safety are a priority, promoting long-term financial benefits of a change is not nearly as effective as exposing the near-term potential Risks of Failure (ROF) for not improving processes and tools.

So how do we make the case for a new approach with CM/DM tools when management support and funding is an issue? The first step is to make sure you have a seat at the table where decisions are made as I discuss in this recent CMsights post “Elevating Configuration and Data Management Inside a Company.”

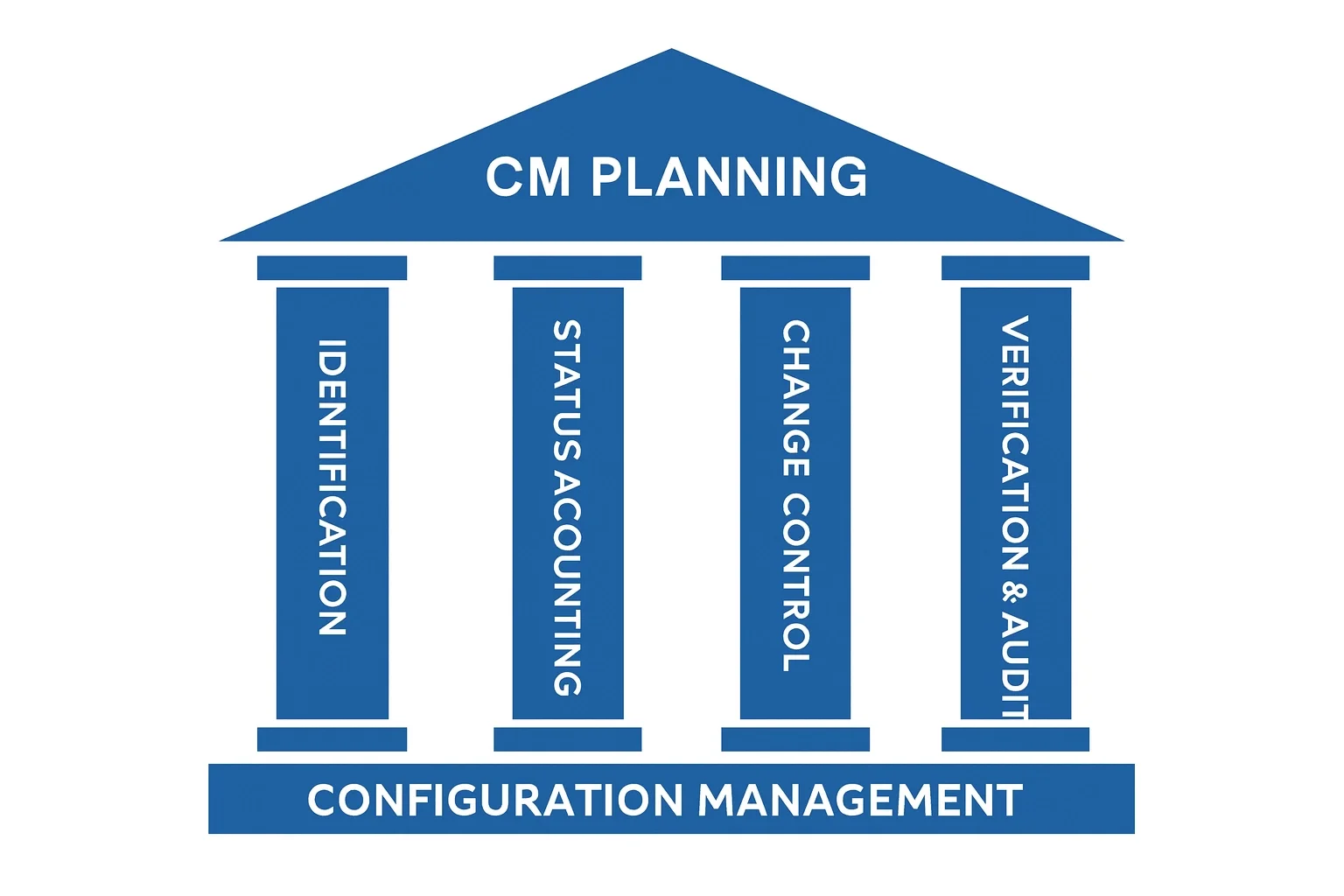

Once that is accomplished, I would start with leveraging the EIA-649 industry standard for CM. There are three fundamental requirements in the standard that are difficult if not impossible to be satisfied with spreadsheets and shared drives. These all fall under the Configuration Status Accounting (CSA) section of the standard.

CSA-1: CSA provides an accurate, timely information base concerning a product and its product configuration information throughout the product life cycle.

CSA-2: Information about the product and the product configuration are captured as CM tasks are performed; reporting is accessible to support program/project activities as needed.

CSA-3: Metrics derived from the configuration status accounting information are used to evaluate and improve CM process effectiveness.

Without support of these requirements how could a manager pull the performance metrics for:

current open changes

changes closed over a given time period

on-time release for drawings and changes

cycle time for models, drawings and changes

first pass yield for the change control board

as-built vs as-designed comparison

open vs closed variances

recurring variances

It has been my experience that there is no efficient way that a CM specialist, much less a manager without expert training, could extract this information for multiple programs or projects in real time without a proper CM software tool. Even if they eventually could, how much manual effort would be involved in such an endeavor and how error-prone operator-dependent is the process?

Outside of status reporting there are numerous other core CM functions and workflows where the use of spreadsheets is cumbersome at best and untrustworthy in many other cases. Examples of these requirements can be found when inspecting the CM capabilities and CM functionalities of a true CM software tool like CMstat’s EPOCH CM.

The same goes for Data Management where one needs to track, submit, orchestrate disposition, reconcile comments, and deliver (and often resubmit) all the data deliverables specified in CDRLs, SDRLs, and SOW requests. This is also unwieldly if not impossible to perform in a repeatable, reliable, secure, and traceable manner without an appropriate DM tool.

As example to assess how well a process is performing, say you want to pull metrics on:

CDRL delivery schedule and delivery lookahead

on-time delivery of CDRLs

on-time receipt of SDRLs

accepted or rejected by CDRL and submitter

customer comments

data accession list (DAL) for all new data items in the repository

records management/retention metrics

when to review data for archive or disposal

How do you accomplish that in spreadsheets and internal drives? The old axiom for CM, DM, and asset tracking applies: If you can't find it quickly, it might as well not exist and you need a new approach with supporting tools.

After presentation of a technical justification, such as the above, the job has only one-third done. A financial business case must often be constructed which I will cover in a future post, diving in to the details on what constitutes a good cost/benefit analysis for CM/DM processes and tools.

I would also include in an internal pitch helping managers comprehend the risks for not taking action as we discussed in the post “Getting Managers to Care About Configuration Management.” The urgency for this comes from current headlines in the aviation industry that should compel every A&D manager to rethink their CM/DM processes. In recent aircraft incidents there are reported to be examples of:

quality procedures being skipped

missing work order instructions

approval of change orders absent

data and documentation that can’t be located or was never created

products not being installed, serviced, or reinstalled properly

quality inspections and regulatory audits finding one after another deficiencies

faulty communication and collaboration between suppliers and OEMs

items that should have been tagged as CIs

shadow facilities and processes where rework of suppliers is performed

documents like operating or repair manuals lacking revision control

As discussed often in previous CMsights articles, it is likely that improved or different CM/DM standards, strategies, processes, and tools could have helped to avoid these issues, or at least mitigated the consequences when they did occur.

Federal Aviation Administrator Mike Whitaker was recently quoted as saying:

“Sometime it’s tool management – it sounds kind of pedestrian, but it’s really important in a factory that you have a way of tracking tools effectively so that you have the right tool and you know you didn’t leave it behind.” (FAA Audit of Boeing’s 737 Max Production Found Dozens of Issues - The New York Times)

While Mr. Whitaker in this case was talking about physical tools on the plant floor, as more quality control processes become digitized, the same should be said of having access to the right software tools and knowing you did not leave any data behind.

Learn more about CMstat’s EPOCH software tools for Configuration Management and Data Management HERE that are rapidly deployable, quickly usable, and readily affordable for A&D OEM programs and their suppliers.

In a future CMDM Coaches Corner I will address other common objections from managers such as “don’t we have departmental PDM or enterprise PLM software bought with the expectation that it does all this out of the box?”

Until then, I invite private conversations with those who are struggling to convince their management they need to upgrade their approach and tools before their company ends up on page 1 news. Drop me a note at dallen@cmstat.com.

Receive CMsights

Subscribe to CMsights News for the latest updates from CMstat on Configuration Management, Data Management, EPOCH CM, and EPOCH DM.

Request a Demo

See how EPOCH CM and EPOCH DM support industry standards and best practices in Configuration Management and Data Management.