EPOCH Configuration Management Applications

Inside EPOCH CM : Overview l Applications l Capabilities l Functionality l Benefits l Case Study Coming Soon l Resources l FAQ Coming Soon! l Demonstration

The EPOCH CM software solution, like its predecessor PDMPlus, is a rapidly-deployable best-in-class configuration management application for use in industries with long-life products, equipment, systems and other assets that may operate for years undergoing numerous upgrades, repairs, refurbishments, and configuration changes in the field.

These industries include: aviation, aerospace & defense, marine, rail, transportation, industrial equipment, energy and other high-tech industries. Example user requirements and application uses of EPOCH CM in these industries include for:

Hardware Configuration Management

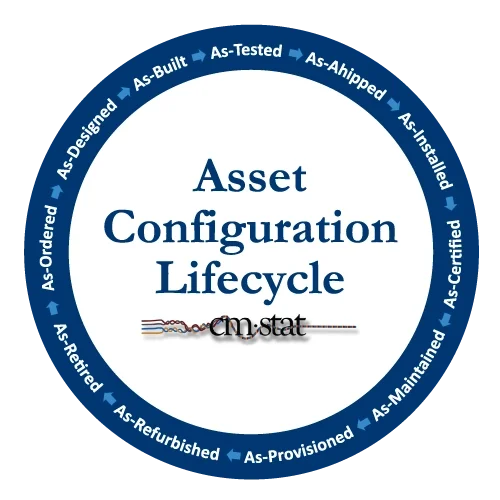

Asset Lifecycle Configuration Management

New Product Development Configuration Management

In-Service and Fielded Equipment Configuration Management

As-Designed, As-Manufactured, As-Deployed, As-Repaired Configuration Management

Fleet Maintenance Configuration Management

MRO Configuration Management

Aftermarket Service, Repair and Refurbishment Configuration Management

Model Based Digital Twin Configuration Management

Tech Pubs, Manuals, & Documentation Configuration Management

Procurement, Logistics & Supply Chain Configuration Management

Regulatory Compliance Configuration Management

R&D Lab and Testbed Configuration Management

Site and Network Configuration Management

Systems Engineering Configuration Management

These application all share in common the need to perform rigorous configuration management over the “long digital tail” of the As-X product lifecycle beyond the OEM’s original As-Designed, As-Built, and As-Released configuration.

The use of Configuration Management software within these different industries and varied application uses is driven by many of the same problems, pains, and performance gaps. Which of these configuration management challenges does your organization experience?

the sheer volume, complexity, and variations in configurations of component parts, design requirements, product deployments, and complete systems overwhelms legacy methodologies, spreadsheets, and software tools

the actual as-deployed and as-maintained configuration has evolved to be very different from what was as-shipped or as-installed

time and effort required to find and verify accurate configuration information eats into the project schedule

lack of confidence in producing upon demand real-time live configuration of deployed assets by specific lot number or serial number

discovery of where-used and analysis of change-impact on as-deployed configurations is unwieldy or untrustworthy, especially for systems operating far downstream of the OEM’s engineering release

management of processes that create, use, or revise configuration data is absent, ad hoc, or broken; much less automated or optimized

losing track of the change process due to changes being made without approval or enterprise awareness, or change history information unavailable, inaccurate, or obsolete

losing configuration control prior to delivery with products produced that are not conforming to requirements, or data and document deliverables not conforming to what was released

losing configuration control after delivery from not being able to track what components are installed on serialized end items

what’s actually bid or delivered by the contractor is not what was specified or bought by the customer

failing the Product Configuration Audit mandated by the contract or program office

lack of baseline configuration management visibility along with inability to identify and track configuration items over their individual lifecycles

processes and procedures for mass customizations and variant management are themselves one-off customizations

difficulty in keeping all the different or downstream BOMs accurate and synchronized with engineering changes across all product variants or lot/serial numbers

installing unauthorized parts, purchasing obsolete parts, and work stoppage due to lack of approved parts

parts produced for the wrong configuration without visibility to alternate or substitute parts that are authorized due to lack of proper communication and documentation

software versioning and releases not compatible with hardware releases

manufacturing inventory, tooling, and processes are misaligned with product configurations

reject, rework, or scrap rates are too high due to old or wrong specifications

installation instructions, work orders, test procedures, training manuals and service bulletins are often obsolete because of configuration inaccuracies

integration and complexity of CM for the supply or service chain that has design and change authority

configuration of digital twin models for service is hard to create or maintain, much less synchronize with the actual physical asset

service contractors not having access to the OEM’s product configuration data or being overly-constrained to use only that product data

completeness, accuracy, and security of data retention and document repository is undependable

extended lifecycles of assets that are in-service for decades creates extraordinary LOTAR burden on CM data

sustainment groups are unable to locate documentation or other historical artifacts

failure to maintain, document, and track ITAR Compliance

certification and other documentation records not matching the true status of the deployed configuration

without a CM Plan the requirement for CM processes and tools are constantly in flux

program management and project budget suffers due to a lack of visibility into CM problems and challenges

Next, learn about the capabilities of EPOCH CM that allow it to address these challenges by examining EPOCH CM Capabilities.

Receive CMsights

Subscribe to CMsights News for the latest updates from CMstat on Configuration Management, Data Management, EPOCH CM, and EPOCH DM.

Request a Demo

See how EPOCH CM and EPOCH DM support industry standards and best practices in Configuration Management and Data Management