PDMPlus Configuration Management Applications

Inside PDMPlus : Overview l Applications l Capabilities l Functionality l Features l Benefits l Resources l Demonstration

The comprehensive capabilities of PDMPlus make it a best-in-class hardware configuration management tool for many important applications of CM found in the aviation, aerospace & defense, marine, industrial equipment and other high-tech industries. Example aerospace configuration management applications include:

Hardware Configuration Management

In-service Asset and Fielded Equipment Configuration Management

R&D Lab and Testbed Configuration Management

System, Site, and Network Configuration Management

Aftermarket Service and Warranty Repair Configuration Management

These aerospace configuration management applications all require CM software that provides deep yet usable capabilities for dealing with the as-managed configuration.

Let’s examine a number of these CM applications for PDMPlus starting with hardware configuration management.

Hardware Configuration Management

Not all industry applications of aerospace configuration management are for physical hardware. Software, firmware, applications, processes, and services also have their own distinct configuration management challenges, terminology, requirements, standards, best practices, and tools. However, the practice of configuration management and change control for hardware components, assemblies, and systems is considered the most demanding CM application. With the focus of PDMPlus on CM applications, all of the most advanced CM capabilities, standards, and best practices have been incorporated. The most important capabilities of PDMPlus which enable superior hardware configuration management include:

Interactive BOM management

Item/Part Identification and Management

Multiple Product Line Management

Graphical Product Structures and Where-Used

Configuration Item Identification

Change Control Request, Proposal, and Order Tracking

Baseline Management

Selective Hierarchical Configuration Level Viewing

As-Designed, As-Built, As-Maintained Tracking

Support of Serialized Assembly Records

Document Version Control

Action Item Tracking

Change Impact Assessment and Traceability Audits

Multi- and Single-level Used-on Queries

Review and Approval Workflow Automation

Regulatory and Compliance Reporting

Secure Web-based Client Access for Suppliers and Service Partners

In-Service Asset and Fielded Equipment Configuration Management

Managing the configurations of large, expensive, or mission critical assets that are in-use in the field requires a complete CM system that can operate alone or firewalled as is often needed, as well as with other applications when sharing controlled product data updates. Numerous CM capabilities are required to provide for the efficient and reliable configuration management of in-service assets many years after they left the OEM’s shop floor. The most important PDMPlus capabilities which support in-service CM are:

A Database of Authority for Live Configuration Data

Configuration Item Management

Baseline Management

Change Management

Impact Assessment

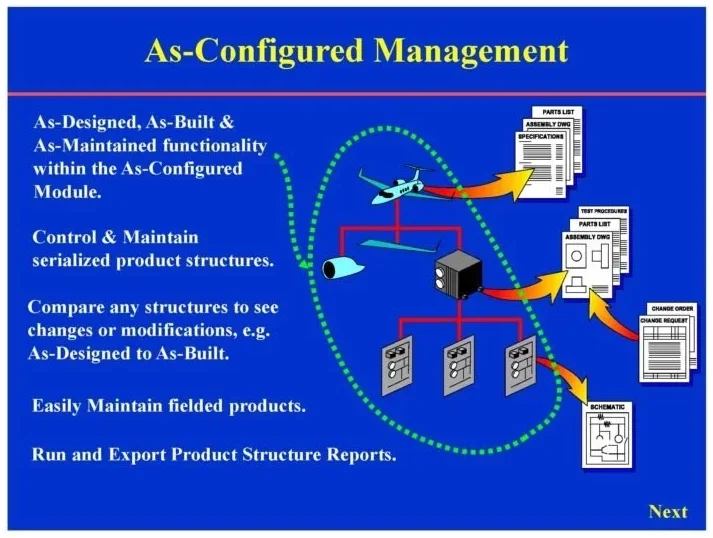

As-Configured Management

Document Control & Review

Workflow Automation

R&D Lab and Testbed Configuration Management

R&D lab and test platforms can range from small experimental bays such as an avionics test bench to large structures such as a HVAC test facility or a global-spanning telecommunication networks. Whatever the deployment environment, the requirements they have for performing CM of their assets are often the same.

The baseline As-Designed record, along with the separate iterations of the As-Tested configurations, must be recorded, managed, tracked and available for comparison. That includes not only parts, serialization and reference designation, but associated revision-level documents as well. Comparisons of the As-Tested structures and Document Baselines must be readily available and reportable.

The PDMPlus As-Configured module delivers the functionality required to manage the configuration specifications, history, and documentation of individual lab equipment and testbed facilities. Used in conjunction with the Configuration Item Management and Baseline Management modules, users have a complete and configurable view of all product and documentation.

System, Site, and Network Configuration Management

Managing the configurations of variant product structures or customer configurable systems across multiple geographic sites or dispersed networks is supported by PDMPlus.

At each location the items under configuration control may consist of different release levels of hardware, software, and firmware along with version controlled documentation, service manuals, compliance records, and maintenance history. The challenge is the ability to easily identify and manage the primary product baseline and individual iterations thereafter, as well as the fielded locations and site specific configurations. As example, when a defective or superseded part is identified, it must be quickly identify on what products the part is used, where and in what quantities within the products at various site or networked locations.

PDMPlus explicitly supports the performance of mission-critical CM across systems, sites, and networks by allowing:

Multiple baselines by parts, hardware, software and document CIs

Baseline models that can be based on MIL and EIA Standards

Multiple As-Configured scenarios using the As-Designed foundation

Certification of parts and installations where required

Unique As-Designed, As-Built, and As-Maintained Configurations of multiple sites

Support of large As-Built or Serialized Assembly Records (SAR)

Authorized site personnel to update “As-Built” records with replacement serialized parts through Web based Interface-Asset Tracking

Non-standard reference designation that concatenate reference designations correctly in “As-Built” records

Provide varying levels of granularity in product views and information sets to support different departments such as engineering services and field tech support

Aftermarket Service and Warranty Repair Configuration Management

The configuration management of fielded products performed by the aftermarket service chain, including warranty repair providers, is supported by PDMPlus through the:

Flexible capability for product identification and product structure development isolated or remote from the OEM product engineering environment

Manipulation of As-Built, As-Serviced, As-Maintained, etc. records to reflect real-world configuration and history

Work order association and authorization maintenance work

Version history tracking of serial numbers, bar code, IUID, and SW version

Remove, replace, and refurbish capability with serial history preservation in the As-Configured records

Certification records that verify installs and builds, and capture pertinent data of what type of testing was conducted and the results

To read more about the configuration management capabilities of PDMPlus which power these applications CLICK HERE.

Receive CMsights

Subscribe to CMsights News for the latest updates from CMstat on Configuration Management, Data Management, EPOCH CM, and EPOCH DM.

Request a Demo

See how EPOCH CM and EPOCH DM support industry standards and best practices in Configuration Management and Data Management